Lenses are safety devices that protect you as the last barrier before objects, liquids or particles can enter your eyes, and are made of different materials, the most common to mention a few are: CR9, Acetate and polycarbonate, the latter in It is highly recommended and the one used in lenses with high impact and ballistic impact approvals, as it is made of a more resistant, durable material that suffers fewer scratches.

Safety glasses that comply with ANSI regulations have a marking inside the frame that indicates the following:

Mechanical Resistance: It is the tolerance to the impact of an object traveling at a certain speed.

Optical Class: It is a very important point that must ensure that the lenses do not cause any distortion.

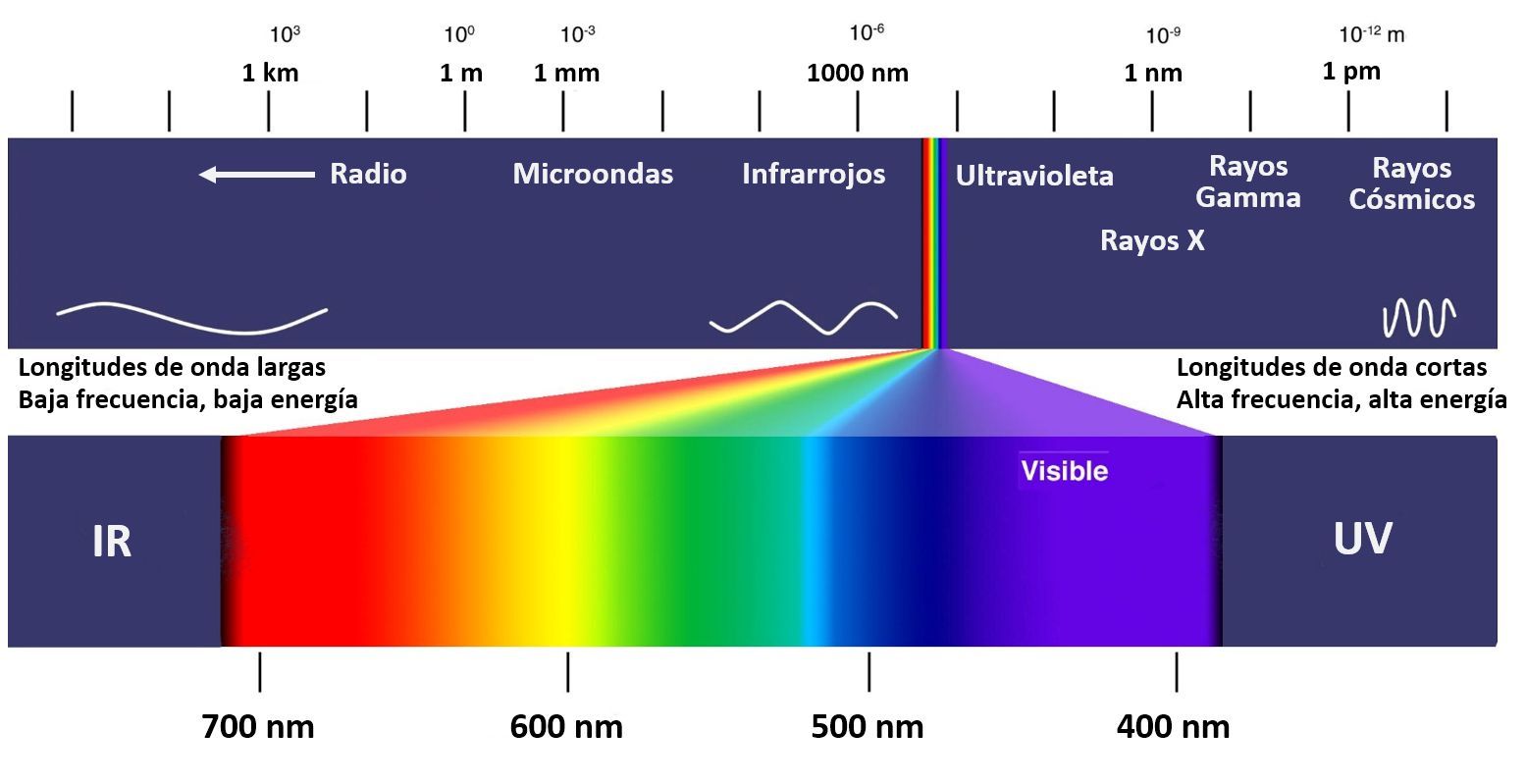

Filter Performance: It is necessary to indicate if they are suitable filters for welding, or to protect from sunlight or if they protect from UV Light.

Protection class: It is one of the least known points but it is important to identify if they offer some level of Visible light filtration

Manufacturer identifier: Provides us with certainty that it is from a known manufacturer and not a relabeled product.

The new regulation of the ANSI Z87 + 2020 standard tells us today about the anti-fogging protection that is applied to the protective lens.

People's eyes require protection due to their sensitivity and because they can be irreparably damaged by almost anything that, at a certain speed or force, could pass their natural barriers.

The eyes are also very sensitive to light, to certain temperature changes and to particles that can hit the eyeball, cornea, iris or any of the parts that make up this valuable organ.

It is very important due to the function they perform that the visual protectors have perfect clarity, that is, that they do not divert or obscure the attention of the user; it is necessary that the safety glasses used do not cause distortion either. so that in the same way the worker does not make mistakes or cause accidents due to his lack of vision of the environment.

As I said, lenses or glasses should be the last barrier, that is, guards must be placed in the work processes, or elements that prevent injuries depending on the type of activity being carried out.

When safety glasses are used, it is because the work risks are already known and the intention is to avoid injuries in the event of radiation, splashes, exposure to chemical substances, impacts and other damages. Normally we must select the lenses based on the type of frame, color of the lens, style and of course the classification of the standard that will indicate to us:

Lenses are also classified based on the impact they could receive, this is based on the environment or type of work. Generally in the industrial sector, lenses are designed to overcome certain types of impacts. and that is why the main classifications are

ANSI Z87.1 Basic Impact: In which it indicates that a lens manufactured under this specification must comply with a weight of 500 Grs in a vertical drop from 1.27 M high.

ANSI Z87.1+ High Impact that is designed to offer greater protection in range of objects

ANSI Z87.1 Ballistic Impact: Finally, the same regulation includes the range of ballistic impact ; they must be able to resist impacts up to .15 caliber at 700km/h and .22 caliber at 600km/h respectively, and require a resistance 7 times greater than those Z87 standards

It is very interesting to know how the standard has evolved as a result of the "flaws" or "improvements" that need to be implemented as accidents and situations are detected that put some people at risk and these conditions are improved in the safety products. , therefore it is very important to stay updated and knowledgeable.

At Bryan Safety the product catalog aims to comply with these regulations and you will always find these products that comply with the latest trends. Consult your representative if you are looking for a particular review.

9 comments

D Change

Hi, I do believe your website may be having internet browser compatibility issues.

When I look at your site in Safari, it looks fine but when opening in IE,

it’s got some overlapping issues. I merely wanted to give you a quick heads up!

Aside from that, wonderful site!

D-change.net

Hi there to all, the contents existing at this web site are genuinely amazing

for people experience, well, keep up the good work fellows.

d-change.net

You’re so awesome! I do not believe I have read a single thing like that before.

So good to find someone with a few unique thoughts on this issue.

Really.. thanks for starting this up. This web site is one thing that’s needed on the

web, someone with a little originality!

d-change.net

Thank you, I have recently been searching for info approximately

this subject for a while and yours is the best I’ve discovered

till now. However, what about the conclusion? Are you

positive about the supply?